Furnaces, boilers, fractionating columns, reboilers and countless other examples of industrial equipment depend on the combustion of fuel to work properly. However, this process does not come without its challenges, given the fact that gas and particle emission is harmful to both our health and the environment. It needs, hence, to be regulated by governments all over the world. That is the reason why industrial processes require adequate dust removal systems whenever fuel burn is involved in their operation.

For filtration systems to work, particles in suspension in the air need to be separated and discarded. This process is called dust collection or dedusting. Separation can be done by bag filters, cyclones or electrostatic precipitators, for instance. The removal of particulate material can be done by chain conveyors or water collectors. This material can also fall directly into buckets.

The dedusting system needs to ensure that particles are removed from the equipment. However, the difference between the atmospheric pressure and the pressure in the equipment needs to be maintained. Many industries use rotary valves, which have a rotor that spins a set of pallets to discharge the particles, for that purpose. The biggest drawback of this solution is that these valves are not sealed. In addition, the rotary valve has a higher rate of wear and tear, often requiring corrective maintenance. Proper operation of the dedusting system with no leakage of pollutants requires a fully sealed valve, such as the double flap valve.

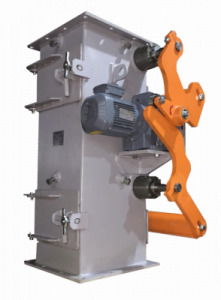

The Uniprest Double Flap Valve

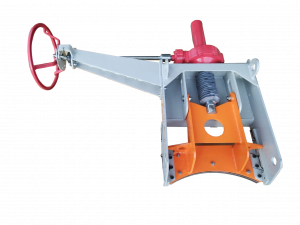

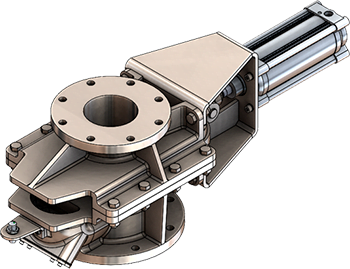

Double flap valves, also known as double pendulum valves or double dump valves, are used to handle dry bulk material in industrial applications. They can be suitable for use with fine powders or larger, irregular-shaped particles. The valves work thanks to the combined operation of two independent chambers. The first plug opens, allowing dust to fall into the first chamber, and then closes, making sure there is no leakage. The second plug subsequently opens, discharging the material and maintaining the seal. The plugs can be flaps, cones or cups. The mechanism can be actuated by a pneumatic cylinder or by a geared motor.

Not all double flap valves are the same. Different manufacturers produce a range of models using different technologies and materials.

The Main Features of the Uniprest Double Flap Valve

High leak tightness. The Uniprest valves have a very high leak tightness (sealing capacity), which prevents the entrance of false air and reduces the emission of particles in both the work environment and the atmosphere (in compliance with Brazilian regulation standards).

Shaft bearings with a highly efficient sealing system. The shaft acts as the leverage point of the plug of a flap valve. These parts are typically very simple and do not have adequate sealing systems. The bearings of Uniprest valves, however, have a highly efficient seal.

Long-term robustness. Our valves are built with noble parts and advanced linings. The shell is made of carbon steel or cast iron, which makes sure the valves have a long service life and higher resistance.

Very low maintenance. Uniprest valves have a long life span and rarely require corrective maintenance. On average, our valves can operate for up to a year without any maintenance required. When it is necessary, the only action usually required is to replace the seat or the plug, parts that can be easily accessed.

Position sensors. The sensor system can detect whether the plugs are open or closed in real time. It can also detect valve blockages due to overload.

Safety lockout system for inspection and maintenance. Built with the cooperation of valve operators at the plants, this part makes inspection, cleaning and maintenance procedures safer. Even when it is disconnected or out of the equipment, the valve plug can be locked in the open position, without the need for a belt or rope.

Protection screen. The screen protects the actuation mechanism and the counterweight system of the valve, which brings more safety to the operator and reduces the risk of accidents. All our valves comply with Brazilian regulation NR-12.

Capacity. The discharge flow rate can be adjusted to meet our clients’ needs. The Uniprest valves are able to discard material at rates from 0,5 m3/h to 50 m3/h.

How the valve works

Want to learn more?

What makes Uniprest stand out is our unmatched ability to understand the needs of our customers and offer customized solutions. Let’s talk!

Contact us by e-mail (uniprest@uniprest.net) or WhatsApp ( +55 31 97555-0390). You can also fill in our technical specification form and we will find the best solution for your company.