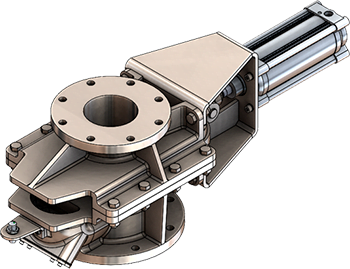

Learn more about our ball valve that was developed to convey fine powders in the dedusting systems of secondary electrostatic precipitators in sintering machines of steel mills.

The aim was to increase the wear resistance of the ball and improve seal efficiency. The previous valve had a ball with chromium-based cemented carbide coating and a PTFE seal actuated by a disc spring.

A new thermal-sprayed coating was developed and applied to the ball and flow guidance in order to offer higher abrasion resistance. In addition to that, we developed a new sealing system using a self-compensating system patented by Uniprest.

The product was tested in the sintering plant for months and showed excellent durability under the most severe abrasion conditions. Neither the ball nor the seal showed apparent wear at the end of the trial period.

Preencha seus dados abaixo para entrarmos em contato com você:

Para solicitar um novo projeto de válvula sob medida para o seu negócios, clique no botão a seguir:

Excelência em válvulas sob medida

+55 31 2535-1232

Avenida Bandeirantes, 940

Belo Horizonte / MG

CEP 30315-000

Faça o download deste material clicando no botão a seguir: