The aim is to discharge a material flow while keeping a difference between the pressure in the upstream and downstream equipment. This equipment can operate under positive or negative pressure.

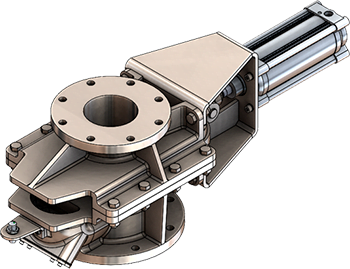

The valves operate using two independent chambers which work independently. Their plugs can be flaps, cones or cups and they can be actuated by a pneumatic cylinder or a gear train.

These valves are used in industrial environments to handle dry bulk materials that range from fine powders to larger, irregularly-shaped particles.

Only Uniprest valves have very high leak tightness, which prevents false air and also helps to reduce emissions of particulates into the atmosphere, as well as into the work environment. This outstanding feature follows the Brazilian safety standard NR-12, as a Collective Protection Measure.

Preencha seus dados abaixo para entrarmos em contato com você:

Uniprest provides maintenance services for double flap and knife gate valves actuated by gear trains, pneumatic and hydraulic cylinders and handwheels. We have the required know-how to maintain and repair valves, considerably reducing the cost of purchasing new equipment.

Check out which are the most frequent questions for this type of product:

Para solicitar um novo projeto de válvula sob medida para o seu negócios, clique no botão a seguir:

Excelência em válvulas sob medida

+55 31 2535-1232

Avenida Bandeirantes, 940

Belo Horizonte / MG

CEP 30315-000